Who We Are

Our Commitment

Our goal has always been to create extremely rugged industrial computers with high computing power and is easy and intuitive to operate. We are the proprietary designer and manufacturer of the entire IPC, including the motherboard. The highest quality standards are placed on all of our industrial computers and we ensure only the best industrial components are used. We will continue to produce and market innovation products that will set new standards in the marketplace.

“As the CEO of noax, I consider it my duty to offer you – our customers – reliable industrial PCs for your application. We want your IT hardware to work easily so that you can have better use of your time. This is why quality, reliability, and ease of service are of utmost importance to us.

Your trust is our motivation.”

Dipl.-Ing. Verena Schechner

CEO

Our History

In response to these needs, we began designing and manufacturing completely sealed industrial computers with no external fans, a critical requirement to meet the needs of rugged environments. noax Technologies AG, was founded in Ebersberg, Germany in 1998.

From the beginning, we have strategically planned each and every detail: from the initial design to the finished product. This allows us to continuously produce and market innovative products that are repeatedly setting new standards. Our first industrial PCs had integrated touch screen panels and a smart heat management system that still meets the high demands of industrial and manufacturing companies worldwide.

With decades of experience in the development, manufacturing, service, and support of industrial PCs, noax Technologies is well positioned to offer our customers the most durable, highest quality industrial PC products on the market.

Our industrial PCs are designed and manufactured at our main facility in Ebersberg, Germany. We have locations in Dortmund, France, Czech Republic, Switzerland and the USA (Charlotte, NC).

Industrial Quality without Compromise

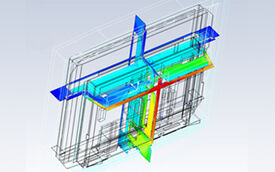

Our Philosophy: From the idea to the finished product

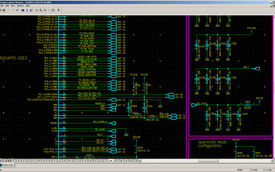

We are the Original Equipment Manufacturer (OEM) of our units, with over 25 years of experience in the industry. We design and develop the entire IPC, including the motherboard. We control the design of all mechanical and electrical parts, requiring the highest quality in every component. With our strict in-house quality management system, we can guarantee the ruggedness of our hardware.

The three pillars of noax IPC proprietary development

1. Mechanics

Pressure & People Proof

- Completely sealed and can be pressure washed from every angle, even while plugged in.

- No vents, cracks or openings.

Sustainable Design

- 80% more resistive than other IPC’s, strong focus on shock & vibration resistance

- Long product life cycle and easy to upgrade

Built to Order

- Completely customizable to fit each customer’s needs

- All legacy ports can be added to all units for compatibility with older equipment

2. Electronics

Proprietary Development & Design of Entire IPC & Motherboard

- Built to Order – completely customizable from the ground up

- Long-term parts availability for at least 7 years

- nSMART software – custom-built, shows all device data (voltages, memory, temperatures, etc.). Custom function keys, works directly with motherboard to record all diagnostic information for service requests

- Award winning design – The Red Dot Design Award – Product Design 2017 – for innovation, design quality, functionality, ecological compatibility & more.

Only Industrial-Grade Parts

- Carefully selected electronic components and circuit parts to perform reliably in the toughest environments.

- All noax suppliers are continually audited to ensure parts meet our strict reliability standards

Universal Connectivity & Compatibility

- Use any standard connection cables (USB, RS232, Ethernet, etc.)

- No expensive proprietary cables needed & no splicing

- Bluetooth 5.0 and WLAN antennas and 2 Ethernet ports ensure fast & constant connectivity

- Electromagnetic compatibility (EMC)

- Consistent use of Intel® chip sets (embedded) for 100% compatibility

3. Quality management

Low Requests for Service

- Annual requests for service are below 1% of all units sold

- Standard 2-year warranty on all units

- Avg. 2 day turnaround time for repairs, 5 business day turnaround guaranteed

3rd Party & In-House Testing

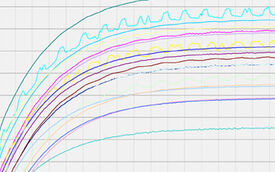

- 48-Hour Burn-In Test – after assembly, all units run for a full 48 hrs. to catch any potential software and hardware issues. The OS (Linux/Windows) is uploaded to ensure all necessary drivers are installed and reliably running.

- Climate changes to test temperature resistance

- Ball Drop – screens are tested by dropping a 500g steel ball from 6ft. directly onto the screen

Certifications

- IK9 – withstands impact of 10 Joules on ALL sides, our touchscreens are 80% more resistive than other IPC’s

- 5M3 – Shockproof and vibration proof

- IP65, IP67, IP69K - waterproof, wash-down/high pressure-proof and dustproof

- ISO 9001:2015 – quality management system (QMS) standard, ensuring our customers consistently receive high quality products and services

ISO 9001: 2015 certification

In order to best carry out our extensive duties and responsibilities we have implemented the model of process orientation from the ISO 9001 standard. We see these directives as guidelines that we can use to meet the particularly high quality demands placed on our products, services and processes.

The fact that they are developed and produced in-house makes it possible for us to adhere to the strictest quality standards and to honor individual customer needs. Come see our quality philosophy at work. Visit our factory in Ebersberg near Munich. At noax, you will see that the “Made in Germany” quality seal offers everything it promises.

Since every good quality management system is based on a continuous improvement process, we invite our customers and suppliers to get actively involved in this process. Why? Because we believe that our customers and suppliers are an integral and existential part of everything we do, including our quality management system.

Sustainability of our industrial computers

Sustainability is our priority, in the design of the equipment and in the manufacturing of our IPCs. This means conserving resources by long runtimes and by using recyclable materials. Our industrial PCs have a long service life and are easy to retrofit and upgrade preventing large amounts of waste from being generated.