From concept to completion

Erdrich, a German-based automotive supplier with more than 50 years of experience, is a mid-sized family-owned company that manufacturers complex metal parts and subassemblies for the automotive industry. Through their experience and commitment to innovation, Erdrich has become a leading global player in the metal stamping industry with a customer base that extends throughout Europe, the US, and Chine with companies like BMW, Mercedes, and Volkswagen.

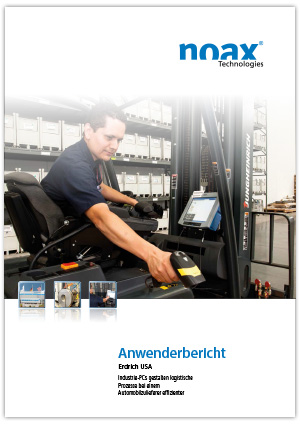

After a week of testing the noax C12, the benefits became apparent. According to Erdrich’s Logistics Coordinator Moises Sanchez, “Before noax, everything that I had to move, I had to write down. Then, I had to find an available computer on the plant floor to enter data. Normally this is not such a big deal, but when you have several people stopping to ask you questions, it can be time consuming. With the noax PC, I can see where I need to go, scan and move parts, and then record the action in real-time…all from the seat of the cab.”

IPC Requirements:

- Completely sealed enclosures

- Simple, intuitive operation by employees

- Easy-to-read touchscreen displays

- High level of reliability to eliminate human error

- Interfaces to various peripheral devices such as bar code scanners

- Use in battery-driven (electric) forklifts

- Professional support and service